Introduction:

Mastering soldering techniques is crucial for building reliable electrical connections in FPV drones. Essential tools include a soldering iron, solder wire, cleaning sponge, and stand. Achieving solid solder joints requires proper temperature control, preparation of the soldering iron tip, attention to wire length, and avoiding prolonged heat exposure. By following these tips, builders can ensure reliable connections and optimal performance in their FPV drones.

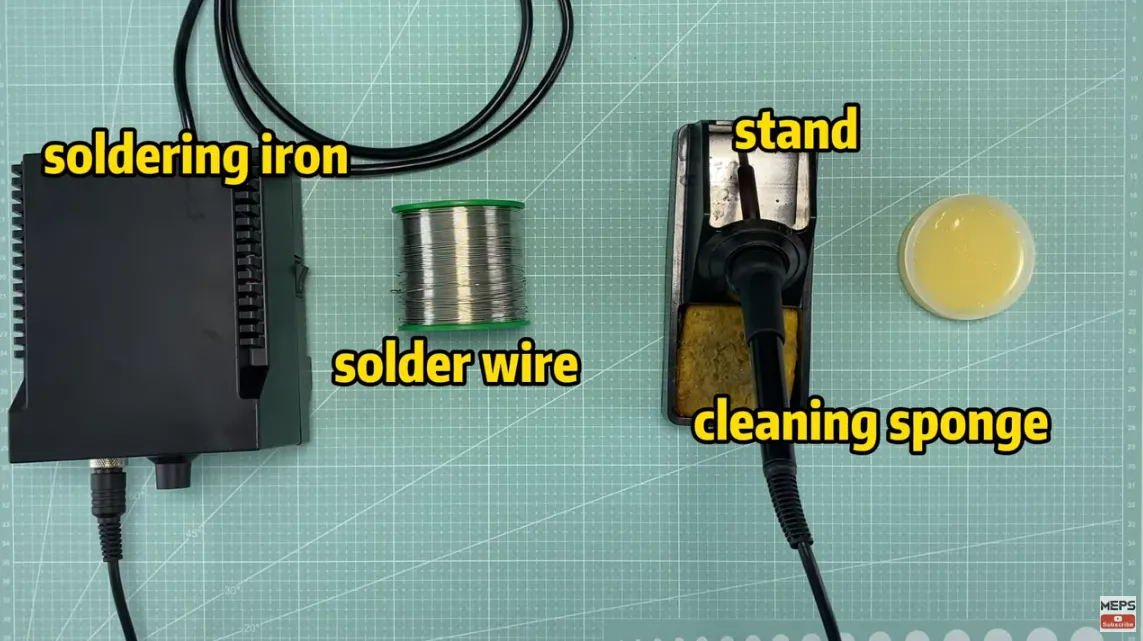

- Essential Tools: Soldering iron, solder wire, cleaning sponge, stand, and adjustable-temperature soldering iron recommended.

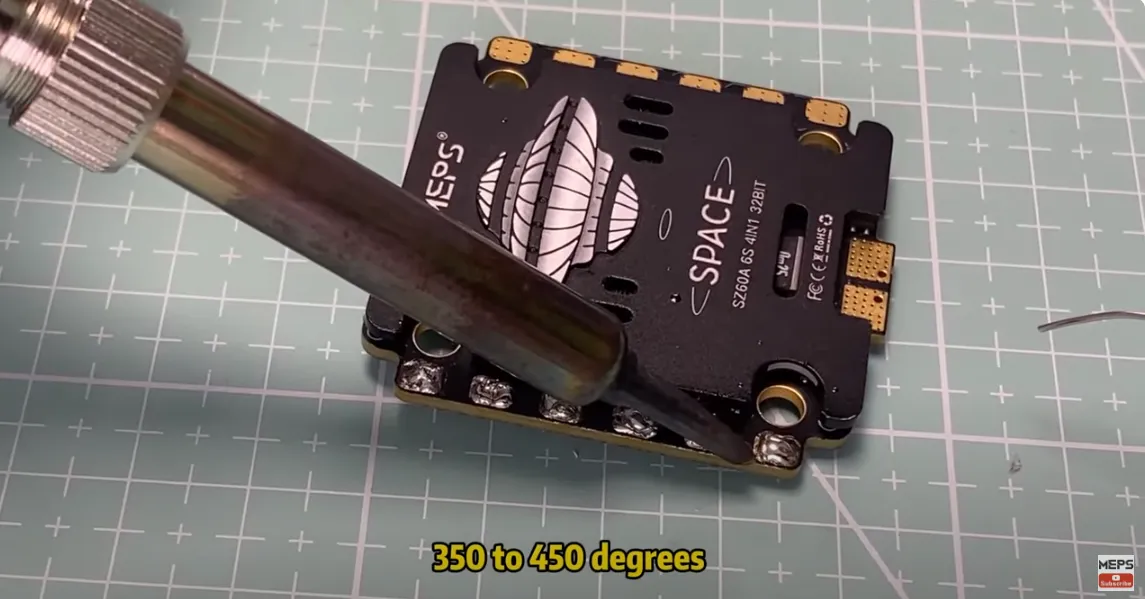

- Optimal Temperature Control: Ensure soldering iron reaches appropriate temperature (350-450°C for large pads, above 300°C for smaller pads) to achieve solid solder joints.

- Preparation of Soldering Iron Tip: Apply a bit of solder to tip before soldering to facilitate heat transfer and proper melting of solder.

- Correct Wire Length: Cut wires to appropriate length before soldering to ensure proper coverage and optimal results.

- Avoid Prolonged Heat Exposure: Prevent damage to pads and achieve perfect joints by avoiding keeping soldering iron on a single pad for too long. Release iron promptly after solder melts.

Video Overview

By mastering the correct soldering tips, you can obtain the solid joints necessary for reliable electrical connections when building FPV drones.

Essential Tools for Soldering

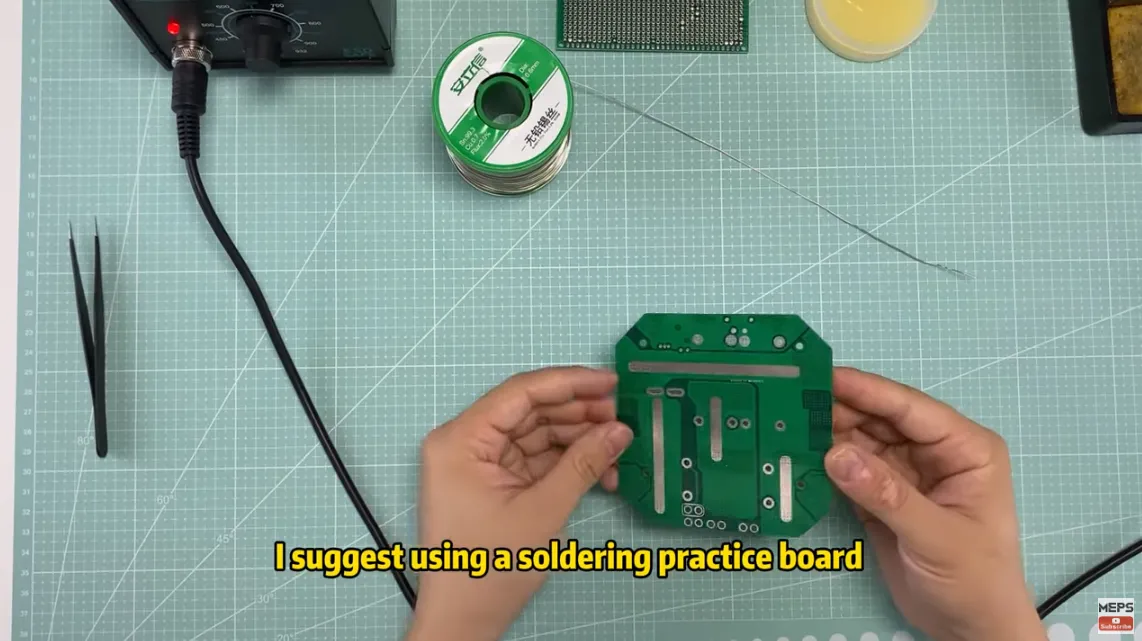

Before diving into the soldering process, it’s essential to familiarize yourself with the necessary tools. From left to right, you’ll need a soldering iron, solder wire, a cleaning sponge, and a stand. Opting for an adjustable-temperature soldering iron is recommended, as higher wattage leads to faster heating. Additionally, choose solder wire with built-in flux for optimal results. Beginners may find it helpful to practice soldering on a soldering practice board.

Melt the Solder Joints

If you want solid solder joints, the first thing to do is to melt them. Yes, you heard that right melt them. Many weak solder joints happen because the temperature is too low which leads to insufficient melting of the tin. Therefore the temperature of the soldering iron tip is very important.

Key Points for Solid Solder Joints

Optimal Temperature Control: Achieving solid solder joints begins with proper temperature control. Ensure that the soldering iron tip reaches the appropriate temperature to melt the solder effectively. Larger solder pads, such as ESC pads, require temperatures ranging from 350 to 450 degrees, while smaller pads like FC pads should be heated above 300 degrees. Insufficient melting due to low temperatures can result in weak solder joints.

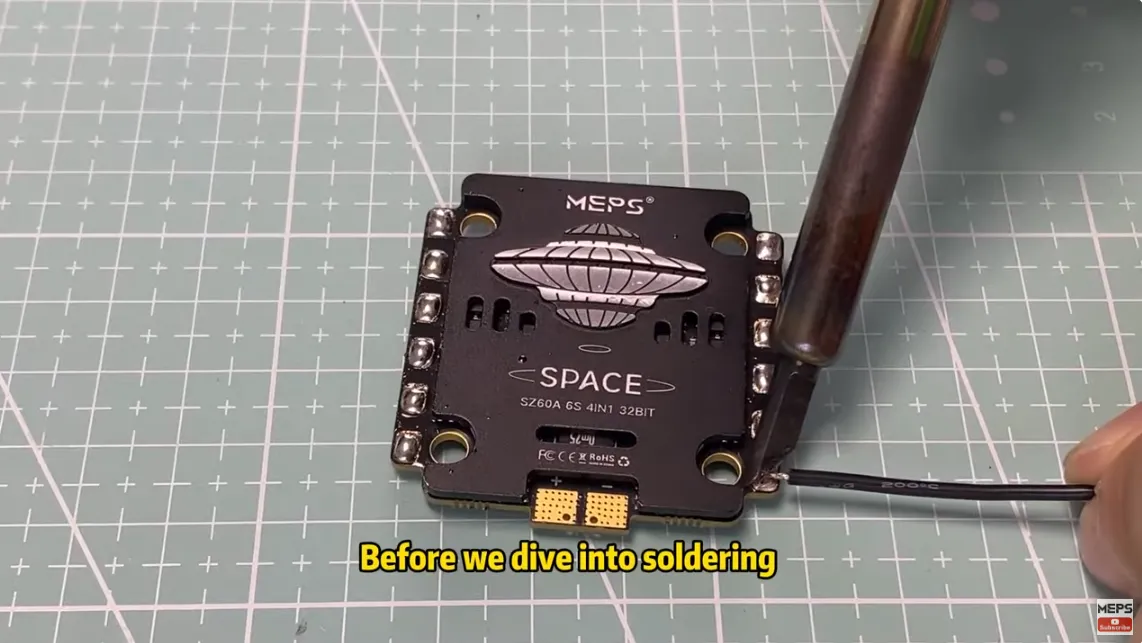

Preparation of Soldering Iron Tip

To facilitate heat transfer, it’s crucial to add a bit of solder to the soldering iron tip before soldering. This helps ensure proper melting of the solder when the iron comes into contact with the pads.

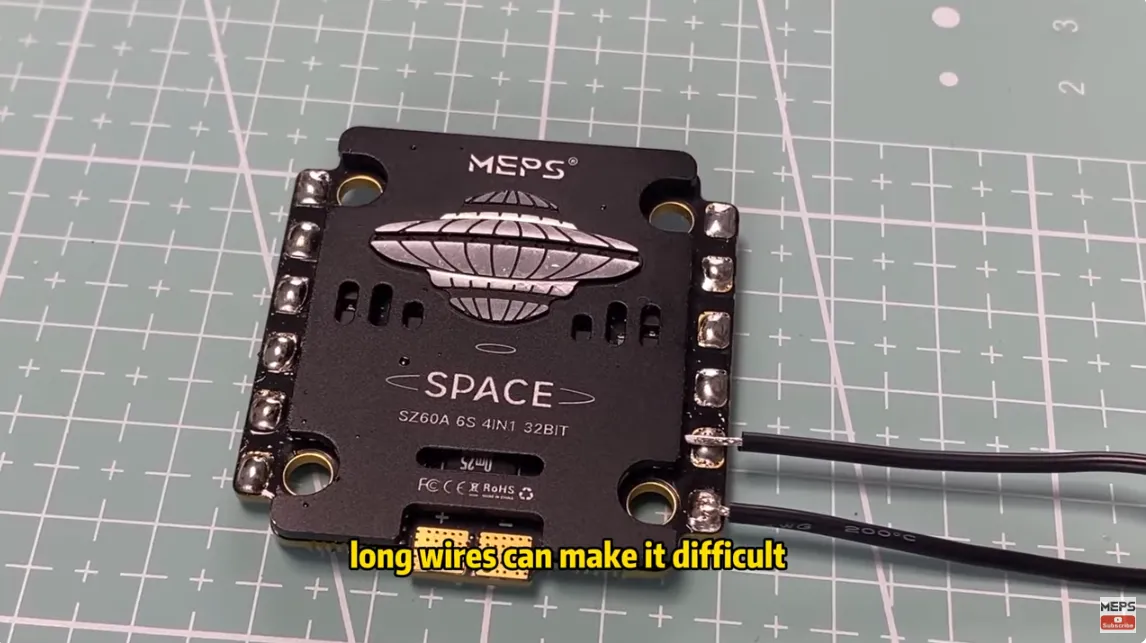

Correct Wire Length

Pay attention to the length of the wires being soldered. Using excessively long wires can make it challenging to cover the entire wire properly. Ensure that you cut the wires to the appropriate length before soldering to achieve optimal results.

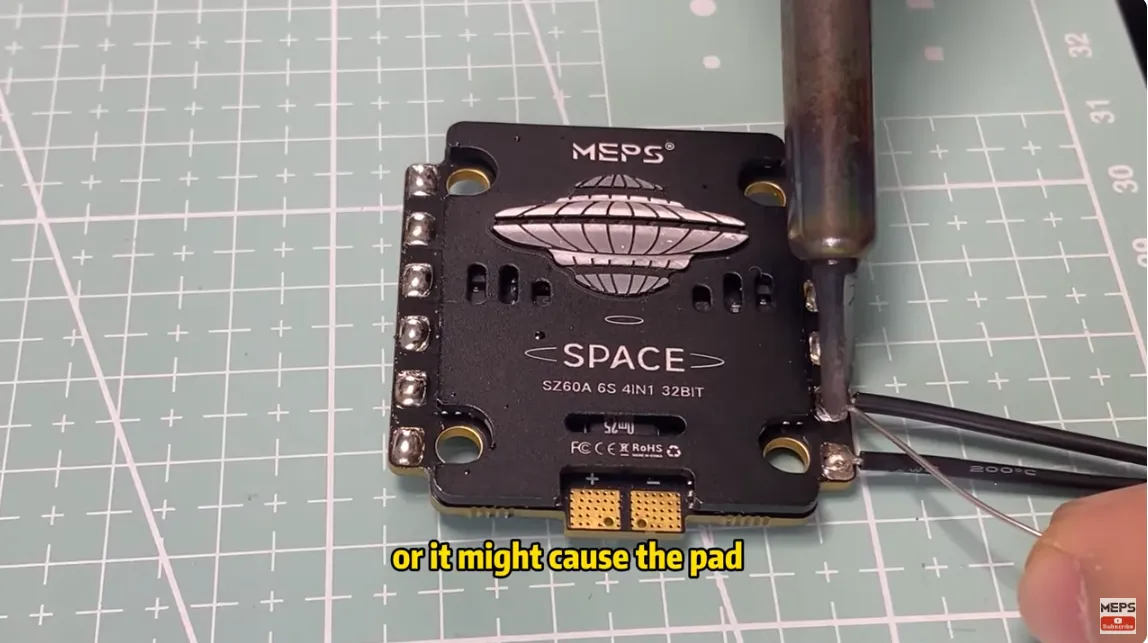

Avoid Prolonged Heat Exposure

To prevent damage to the pads and achieve perfect joints, avoid keeping the soldering iron on a single pad for too long. Prolonged heat exposure can cause the pad to detach, making it difficult to fix. Once the solder has melted, release the iron promptly to ensure a perfect joint.

By following these key points and practicing proper soldering techniques, you can achieve solid solder joints essential for reliable electrical connections in your FPV drone build.