Introduction:

Welcome to a detailed guide on building an FPV drone, focusing on the assembly of the Sector 5 drone using the HGLRC F760 stack and MEPS Space SZ2306 Motors. This guide aims to provide insights and steps for enthusiasts looking to embark on their own FPV drone build, emphasizing the importance of the right tools, preparation, and meticulous assembly for optimal performance.

- Introduction:

- Focus on building a Sector 5 FPV drone using the HGLRC F760 stack and MEPS Space Motors.

- Tools Needed:

- TS100 soldering iron, 3S battery, flux, solder, magnifying glass.

- ESC and Motor Preparation:

- Tin ESCs, solder to MEPS motors, ensure bottom stack is prepared.

- Flight Controller Assembly:

- Assemble with correct orientation, check board direction.

- Soldering Motors and Securing Wires:

- Solder motor wires to ESCs, secure with cloth tape, test with smoke stopper.

- VTX and Camera Setup:

- Install Walksnail Avatar system, ensure correct camera orientation, test with FPV goggles.

- Field Testing:

- Test all systems in the field, check GPS, beta flight settings, and battery.

Video Overview

Welcome, everyone! Today, we’re spending some time on the workbench with my HGLRC F760 stack. I’ve just soldered on the power supply and the capacitor. I’m embarking on a build of my Sector 5, equipped with recently purchased MEPS SZ2306 Motors. These are the MEPS motors 2306 2450 KV motors, and I’m really looking forward to seeing how this thing flies with them.

Introduction to the Building Process

I’ll quickly run through my build process. In case you’re doing a build with a similar flight controller stack, I chose this stack for its popularity and reliability. Additionally, I’ll be adding a VTX – the Walksnail Avatar VTX, which is arriving next week, so stay tuned for that incorporation as well.

Whether you’re doing a similar build or your own, you might learn something here or even have some tips for me. Let’s dive into the building process.

Tools and Preparation

For this build, you’ll need a few tools: a TS100 soldering iron, a 3S battery to power my solder, flux, solder, various tools, and a magnifying glass for the tiny board details.

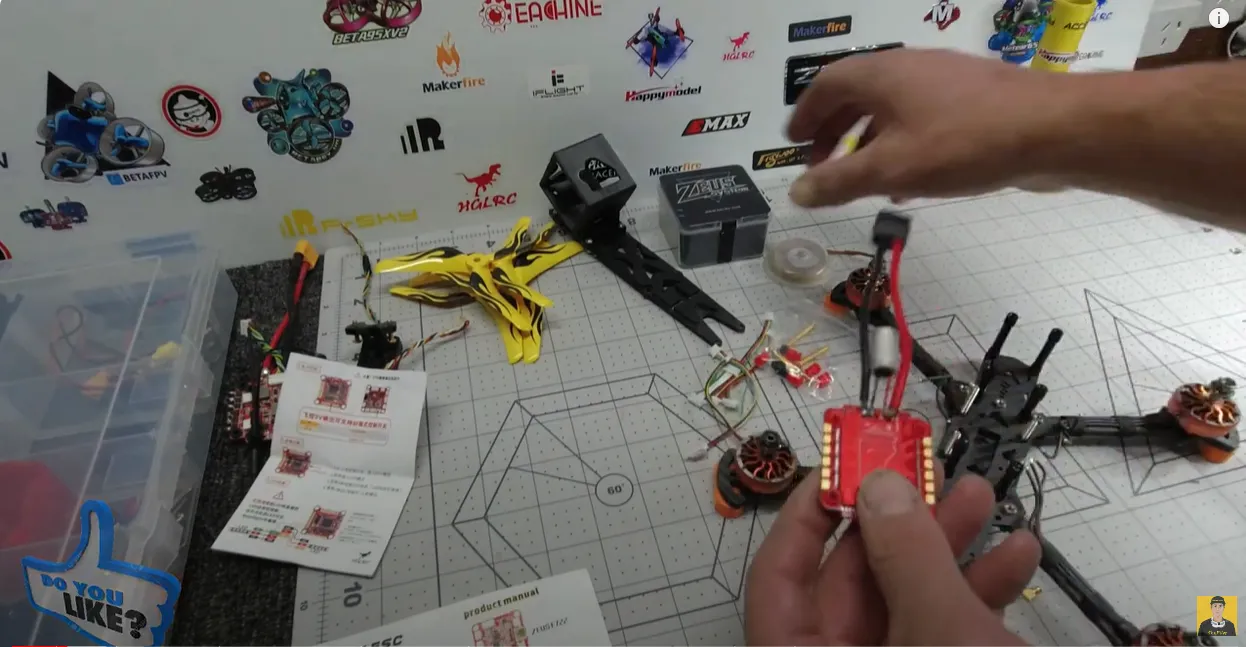

Preparing the ESCs and 2306 Motors

First, I’ll tin up all my ESCs onto my MEPS 2306 motors, ensuring the bottom portion of the stack is ready to go. Remember, tinning the pads before attaching your motor wires can make a significant difference in the quality of your solder joints.

Flight Controller and Stack Assembly

After preparing the ESCs and motors, the next step is assembling the flight controller and stack. The HGLRC pack includes all necessary connectors, dampers, and nuts, facilitating a smooth assembly process.

Correct Orientation

Ensure the flight controller’s direction matches the quad’s orientation. I initially made a rookie mistake by mounting the board backward, which is a common oversight. Double-check the board’s direction before soldering to avoid this issue.

Soldering and Securing the MEPS 2306 Motors

With the correct orientation established, solder the motor wires to the ESCs, ensuring solid connections without any solder bridging. Next, use cloth tape to secure the motor wires to the frame for a neat setup.

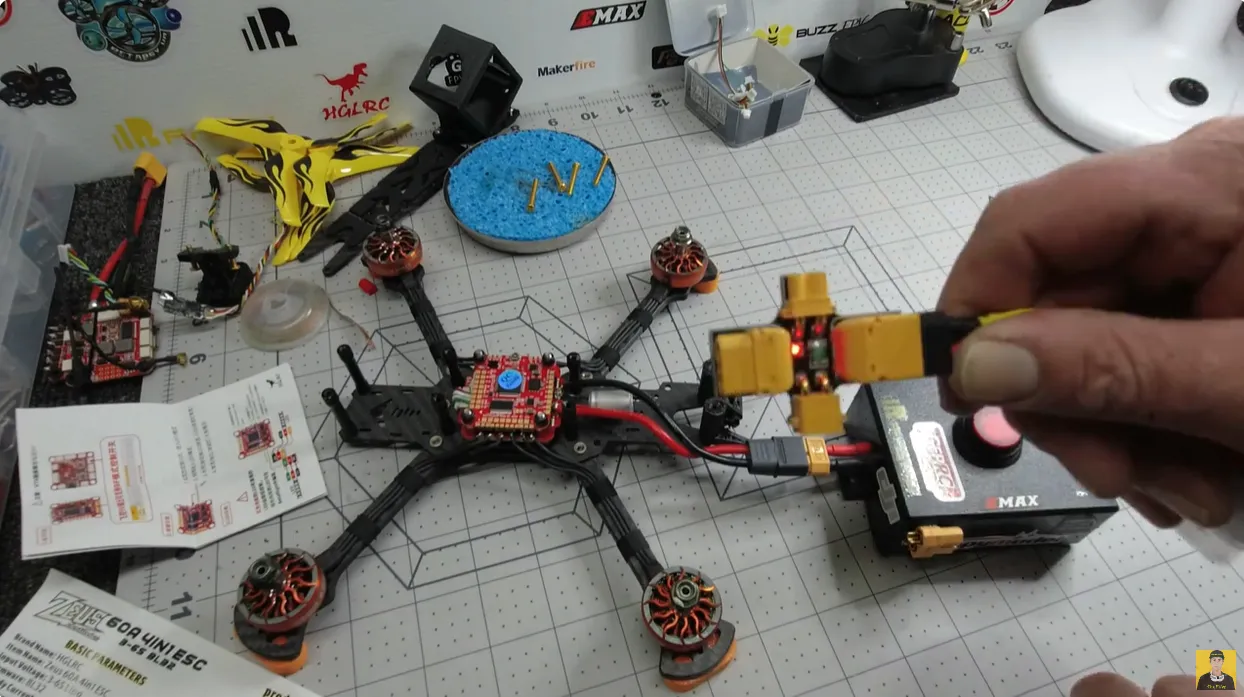

Testing and Final Touches

Before proceeding further, it’s crucial to test the setup with a smoke stopper to check for any wiring issues. Once everything checks out, you can continue with mounting the VTX and any additional components like the TBS Crossfire for telemetry and control.

Setting Up the VTX and Camera

When integrating the Walksnail Avatar system, ensure the camera’s orientation is correct and the system is securely mounted. Testing the setup with your FPV goggles will confirm if the VTX is functioning as expected.

Field Testing

After assembling and testing the build on the bench, it’s time to take it out for a field test. Ensure your GPS has warmed up and all your systems are functioning correctly before your first flight. Pay attention to any beta flight settings or battery issues that may arise during testing.

Conclusion

Building your own FPV drone can be an immensely rewarding experience, offering insights into the workings of your equipment and allowing for customization to fit your flying style. Whether you’re chasing kangaroos or simply enjoying the scenery, the performance of your build will make all the effort worthwhile. Remember to take your time, double-check your work, and most importantly, enjoy the process and the flight. Happy flying!